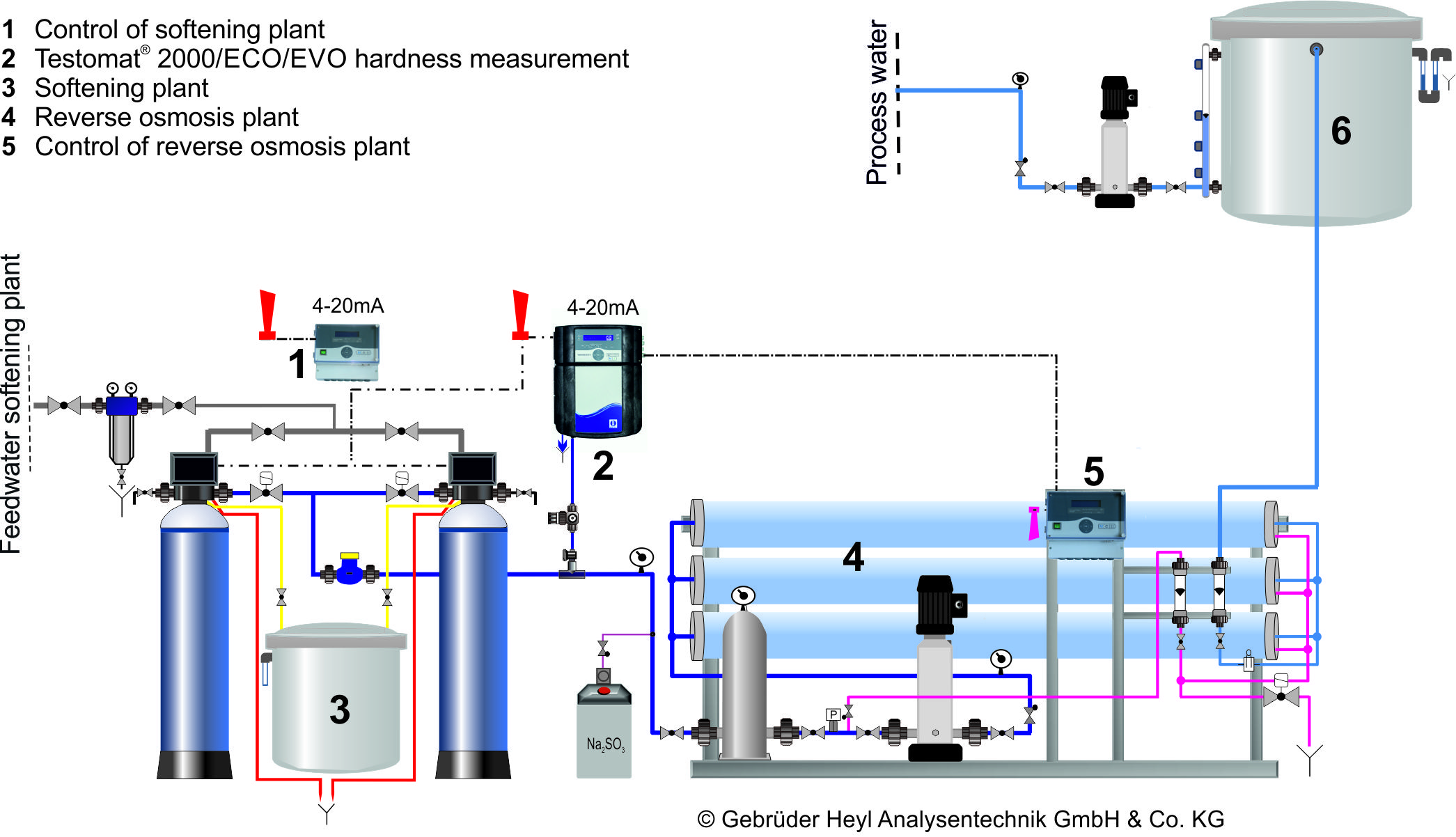

Reverse Osmosis Plants

Water softening and reverse osmosis plant

Controller for Reverse Osmosis Plants

Precise control attuned to the application can contribute to a significant improvement of the entire production process. Therefore, we made it our mission decades ago to provide our customers with application-oriented solutions in which every individual component is precisely attuned to one another.

The following parameters must be monitored:

- Quality

- Salt deficiency in the brine tank

- Correct regeneration cycle

A controller provides optimal control of your water softening plant.

Water softening

Plant operators and plant technicians can increase the efficiency of the boiler water softening process with constant water quality monitoring. This enables operators to recognize whether the regeneration process is running correctly, the resin quality is still sufficient, and sufficient regeneration conditioning agents are present in the right consistency.

The hardness monitors Testomat® 808, Testomat® EVO TH or Testomat 2000® recogize exactly that moment, when a filter has run out and has to be regenerated. This results in less waste water, low salt use, and cost savings due to low energy requirements.