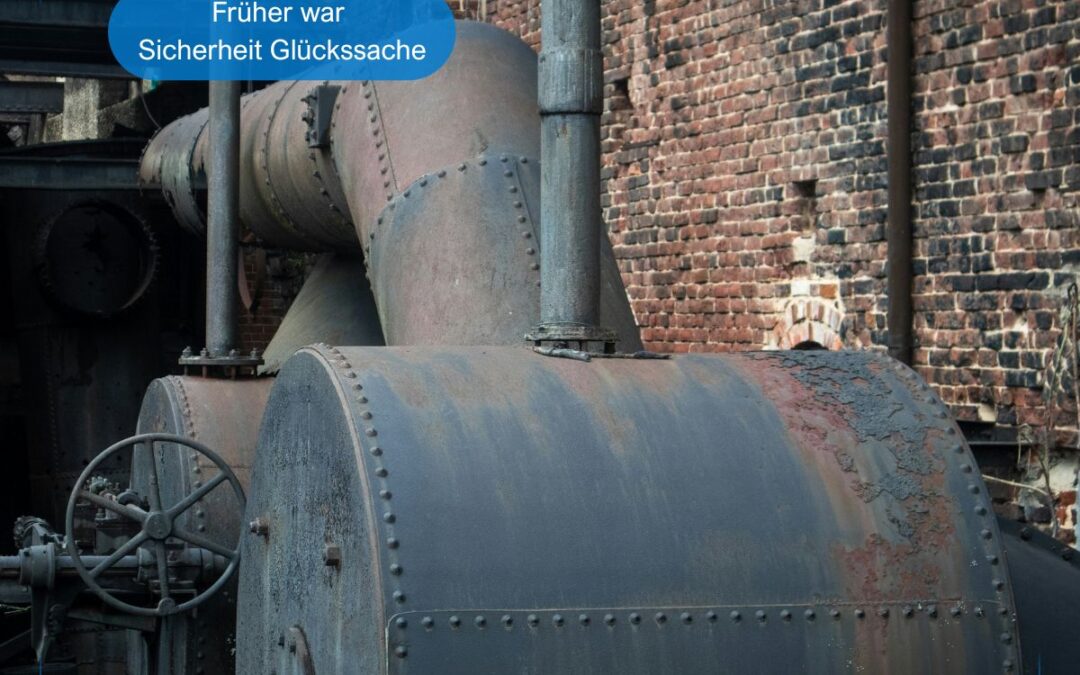

How the Gebrüder Heyl analysis technology shaped the TÜV

At the end of the 19th century, steam boilers were ubiquitous and extremely dangerous to use. Serious accidents occurred time and again: boilers exploded, burst and claimed many lives. In response, boiler manufacturers joined forces to create a clear set of rules for the safe operation of the systems. This was the origin of today’s TÜV.

The basic rules were

- no calcification

- defined wall thicknesses

- controlled water quality

A crucial point here was the measurement of water hardness. And this is exactly where Gebrüder Heyl Analysentechnik comes into play.

The regulations at the time stipulated that Heyl products had to be used for measurement.

Why?

Quite simply because they were reliable.

It was not until around 1961 that measurements were carried out regularly and in a standardised manner across the board. Today, the TÜV specifications are formulated in much more general terms; they ‘only’ concern hardness measurements and no longer refer to specific manufacturers.

This is a fine example of how standardisation and innovation continue to interact today and how measurement technology enables safety.

Measurement creates safety

Post from 11th February 2026